In the fast-paced world of logistics, efficiency is paramount. Every aspect of the supply chain, from manufacturing to delivery, must be optimized to meet the demands of modern commerce. Amidst this landscape, crate mold innovations have emerged as a game-changer, revolutionizing the way goods are transported and stored. By leveraging cutting-edge technology and design principles, crate molds are driving logistics efficiency to new heights.

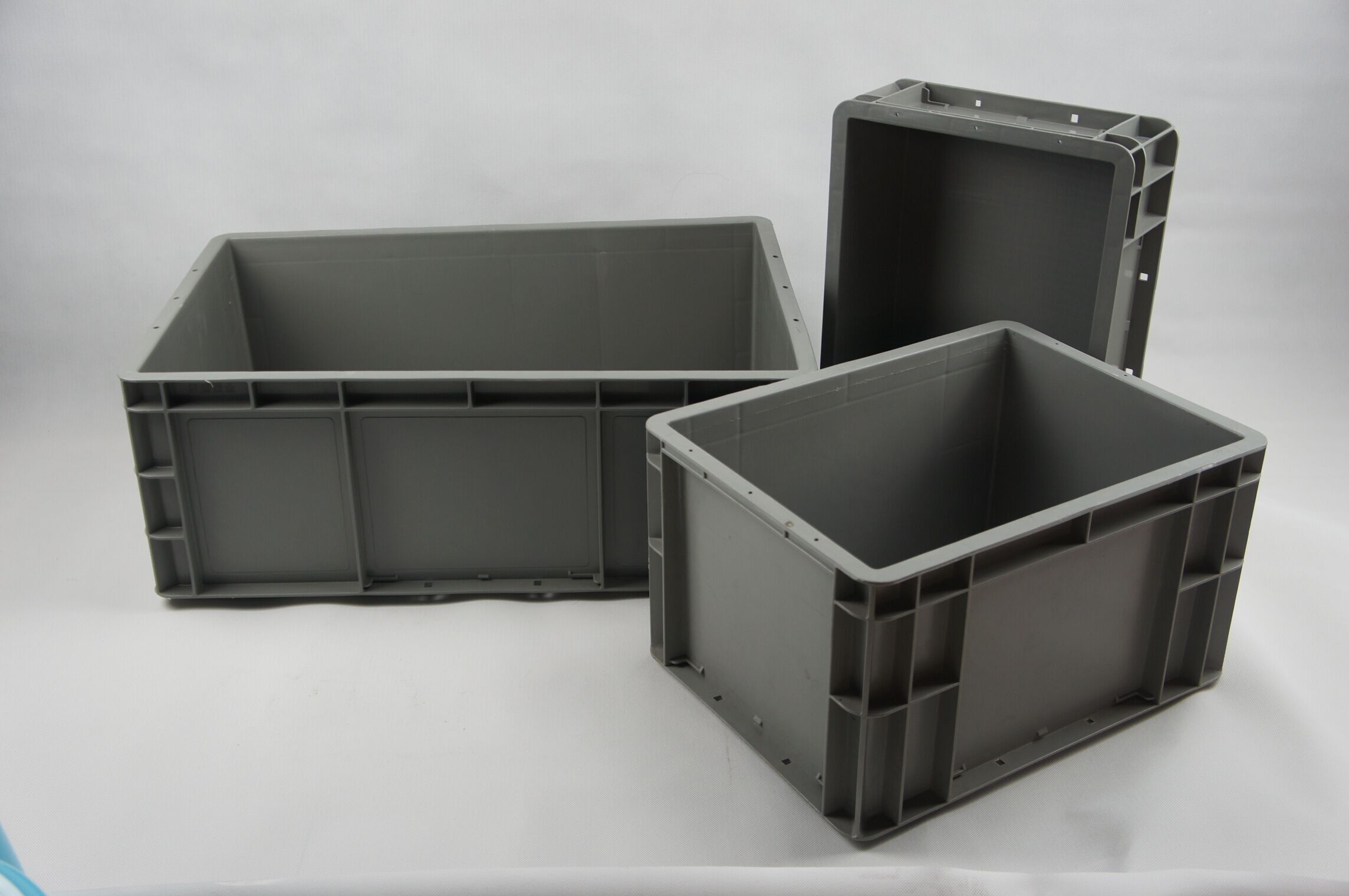

At the heart of this transformation lies the crate mold itself. Traditionally, crates were fabricated using wood or metal, limiting design flexibility and durability. However, advancements in mold technology have ushered in a new era of crate production. Injection molding processes now allow for the creation of highly customizable, lightweight, and durable crates at scale. These molds are engineered to precision, ensuring consistent quality and dimensional accuracy.

The impact of crate mold innovations on logistics efficiency is multifaceted. To begin with, the lightweight nature of injection-molded crates translates to significant savings in transportation costs. Unlike their wooden or metal counterparts, which add considerable weight to shipments, injection-molded crates are designed to be lightweight without compromising strength. This reduction in weight not only lowers fuel consumption but also allows for more efficient loading and unloading processes.

Moreover, the versatility of crate molds enables the design of crates tailored to specific logistical needs. Whether it's optimizing stackability for warehouse storage or incorporating features for automated handling systems, injection-molded crates can be customized to maximize space utilization and streamline operations. This level of customization enhances logistical efficiency by minimizing wasted space and facilitating seamless integration into existing supply chain workflows.

Another key driver of logistics efficiency enabled by crate mold innovations is durability. Injection-molded crates are engineered to withstand the rigors of transportation and storage, offering outstanding resistance to impact, moisture, and temperature fluctuations. This durability not only prolongs the lifespan of the crates but also reduces the risk of product damage during transit. As a result, logistics operators can have greater confidence in the integrity of their shipments, reducing the need for costly replacements and mitigating disruptions to the supply chain.

Furthermore, crate mold innovations contribute to sustainability in logistics operations. By replacing traditional wooden crates with injection-molded alternatives, companies can reduce their reliance on finite natural resources and minimize waste generation. Injection molding processes produce minimal material waste compared to traditional manufacturing methods, further enhancing the eco-friendliness of crate production. Additionally, the longevity of injection-molded crates reduces the need for frequent replacements, resulting in fewer discarded crates ending up in landfills.

The integration of smart technologies into crate mold designs represents the next frontier in driving logistics efficiency. By incorporating features such as RFID tags, barcode labels, and tracking sensors directly into the mold, manufacturers can create smart crates that provide real-time visibility into the movement of goods throughout the supply chain. This enhanced traceability not only improves inventory management and order fulfillment but also enables proactive decision-making to optimize logistics routes and reduce time.

Collaboration between crate mold manufacturers and logistics companies is essential to unlocking the full potential of these innovations. By working closely with end-users to understand their unique requirements and challenges, mold manufacturers can develop solutions that address specific pain points and deliver tangible value. This collaborative approach fosters a culture of continuous improvement, driving further innovations in crate mold design and functionality.

In conclusion, crate mold innovations are driving significant improvements in logistics efficiency across the supply chain. From reducing transportation costs and optimizing space utilization to enhancing product protection and promoting sustainability, injection-molded crates offer a myriad of benefits for logistics operators. By embracing these innovations and fostering collaboration between stakeholders, the logistics industry can unlock new levels of efficiency and competitiveness in the global marketplace. As technology continues to evolve, the future of logistics will undoubtedly be shaped by the relentless pursuit of innovation in crate mold design and manufacturing.

English

English عربى

عربى Español

Español Français

Français