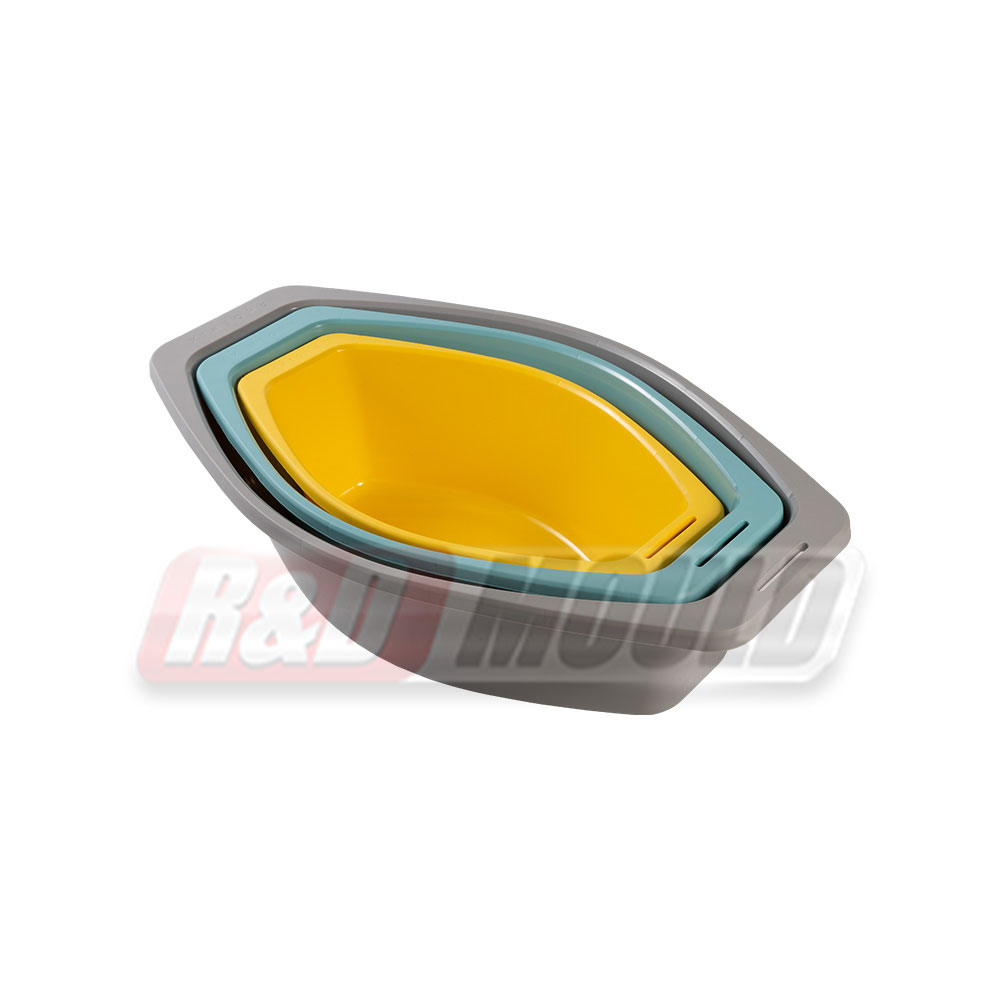

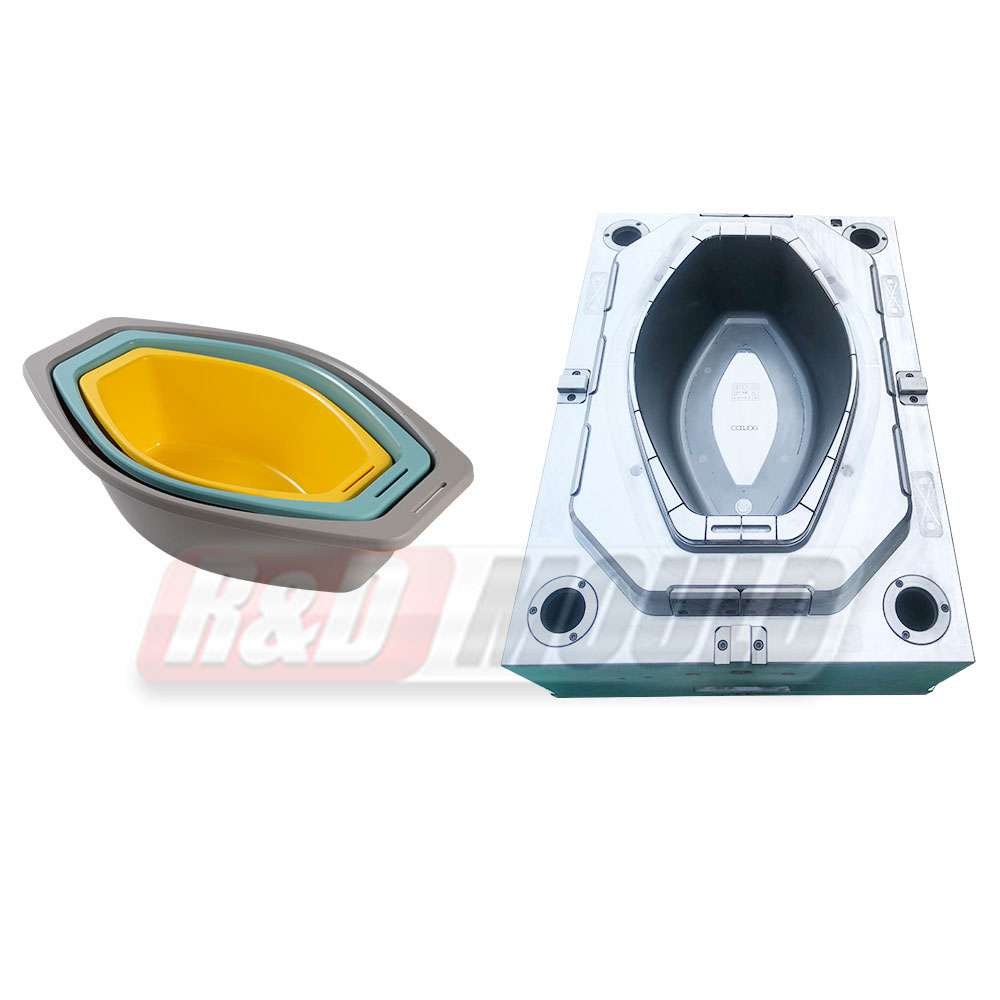

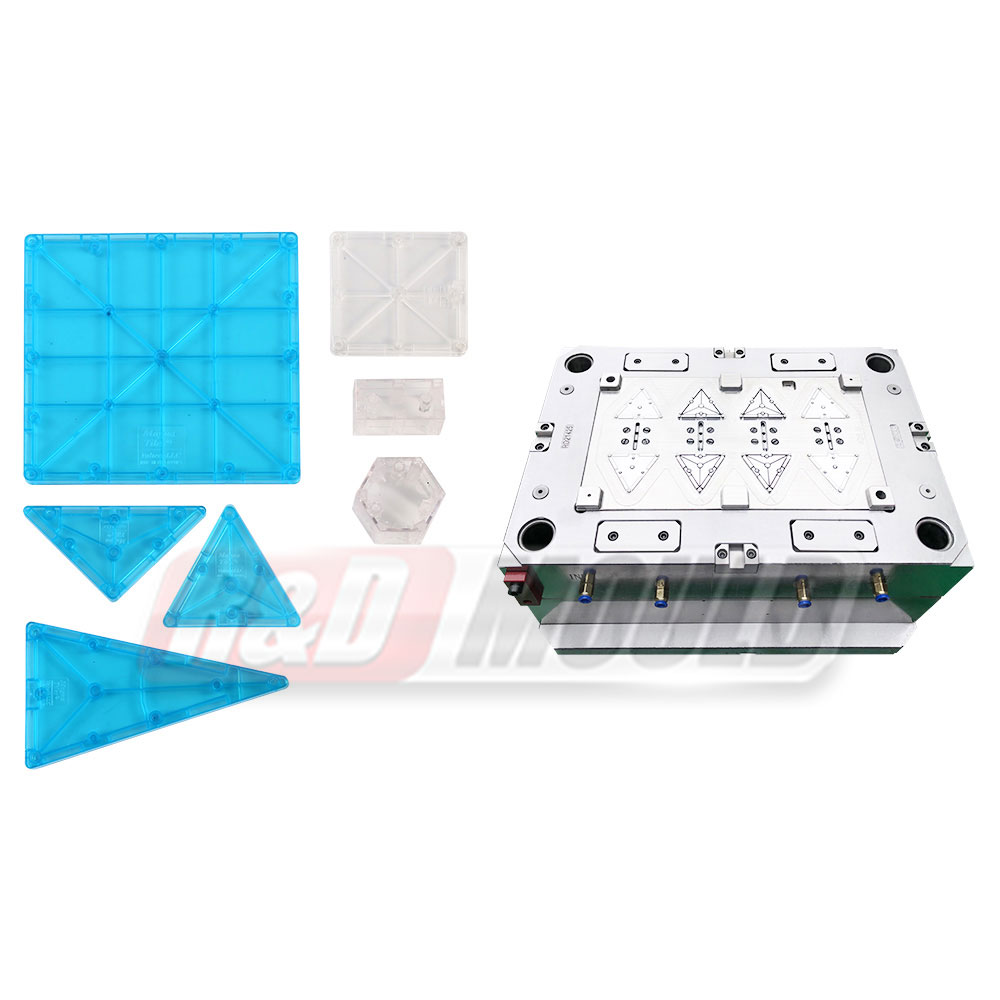

R&D Mould have 18 year experience on manufacturing Baby use mould, Baby Toy Car Mould, Baby Toys mold with various shape and sizes.

Core cavity material usually use: P20 (1.2311) , H13, 718H, 2738...

Mould base: Long Kee standard mold base,

Mould Components: DME/ HASCO standard parts.

Surface treatment: According to product requirements, including skin texture, polishing;

Runner options: 1. Cold runner 2. Hot runner 3. Cold runner + hot runner.

In R&D Mould, we have a complete set of management system. Especially for project management and quality control, ensure successful T1 rate is up to 90%,on-time delivery rate is 95%.

(1)Project Management

Our staffs are able to manage the entire process from the beginning concept to perfect completion. It means higher efficiency ,lower cost, shorten lead-time and much better overall control of the operation. We will make detailed production plan, being monitored strictly by project manager who are rich experienced in mould design, mould manufacture, mould process management.

Every week we will send weekly report with digital pictures to our customer. It is easy for customer to control and understand every process status.

(2)Quality Control

In our factory we have established independent QC department, which takes care of raw-material purchasing inspection, tooling process inspection, assembling inspection and testing part inspection.

English

English عربى

عربى Español

Español Français

Français