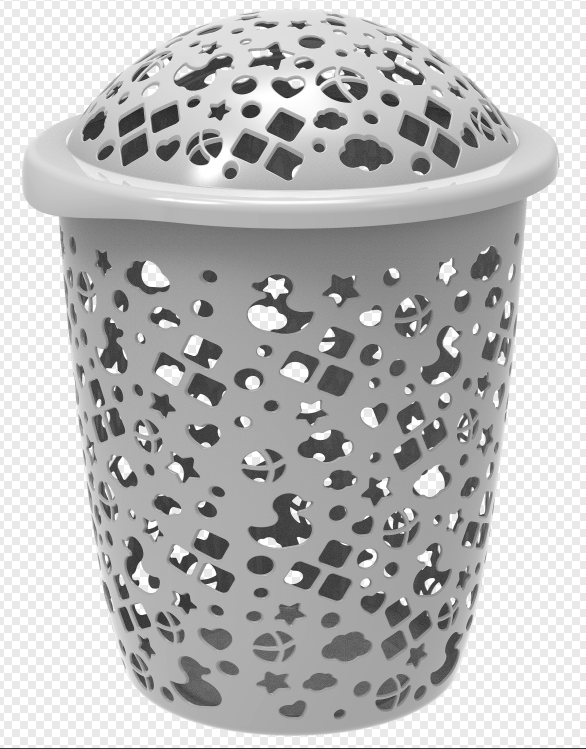

China Basket banneton mould Manufacturer

In the fast-paced world of manufacturing, efficiency is key. One often overlooked aspect that can significantly streamline a company's supply chain is the use of basket moulds. This article will explore the secret to how basket moulds can revolutionize the way businesses manage their production processes.

Basket moulds are not just tools for shaping plastic; they are strategic assets that can enhance productivity and reduce waste. By understanding the intricacies of basket moulds, companies can unlock a world of possibilities in supply chain optimization.

The important step in streamlining the supply chain with basket moulds is to recognize their versatility. Basket moulds can be designed to create a wide range of products, from small containers to large industrial baskets. This versatility allows manufacturers to produce a diverse range of products without the need for multiple moulds, thereby reducing the complexity of their supply chain.

Basket moulds also offer a high level of precision, ensuring that each product is manufactured to exact specifications. This precision minimizes the need for secondary operations, such as trimming or finishing, which can be time-consuming and costly. By incorporating basket moulds into their production lines, companies can reduce these additional steps, bringing about a more streamlined and efficient supply chain.

Another secret to basket moulds lies in their ability to improve material usage. With advanced design techniques, basket moulds can be engineered to use materials more efficiently, reducing waste and lowering costs. This not only benefits the bottom line but also aligns with the growing demand for sustainable manufacturing practices.

The use of basket moulds can also bring about faster production times. By reducing the need for multiple moulds and secondary operations, basket moulds can help manufacturers meet tight deadlines and increase output. This acceleration in production can be a game-changer for businesses looking to stay competitive in a crowded market.

Basket moulds are not just about the physical product; they also play a crucial role in inventory management. By producing a consistent and uniform product, basket moulds can help companies maintain accurate inventory levels, reducing the risk of overstock or stockouts. This precision in inventory management is a critical component of a streamlined supply chain.

In terms of quality control, basket moulds offer a significant advantage. The consistency of products manufactured using basket moulds means that quality can be more easily monitored and maintained. This consistency reduces the likelihood of defects and the need for rework, further streamlining the supply chain.

Basket moulds also have a role to play in customer satisfaction. By ensuring that each product meets the higher standards, basket moulds can help businesses maintain a strong reputation for quality. This reputation can bring about repeat business and customer loyalty, which are essential for a successful supply chain.

As companies look to the future, the role of basket moulds in supply chain management is set to become even more significant. With advancements in technology and materials, basket moulds are poised to offer even greater efficiency and precision. This evolution will not only benefit individual businesses but also contribute to the overall efficiency of the global supply chain.

In conclusion, the secret to basket moulds streamlining your supply chain lies in their versatility, precision, material efficiency, production speed, inventory management, quality control, and contribution to customer satisfaction. By harnessing the power of basket moulds, businesses can unlock a world of efficiency and optimization, setting them up for success in a competitive market.

English

English عربى

عربى Español

Español Français

Français