|

Mold name |

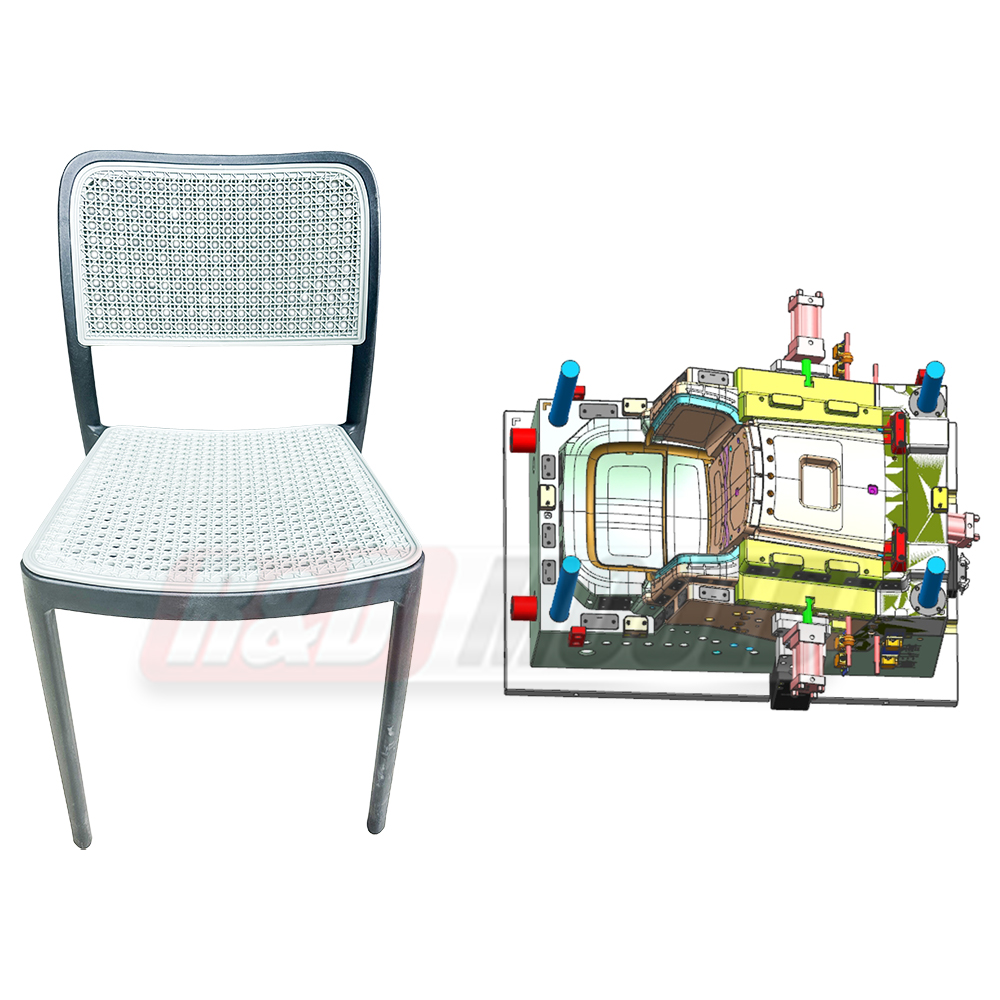

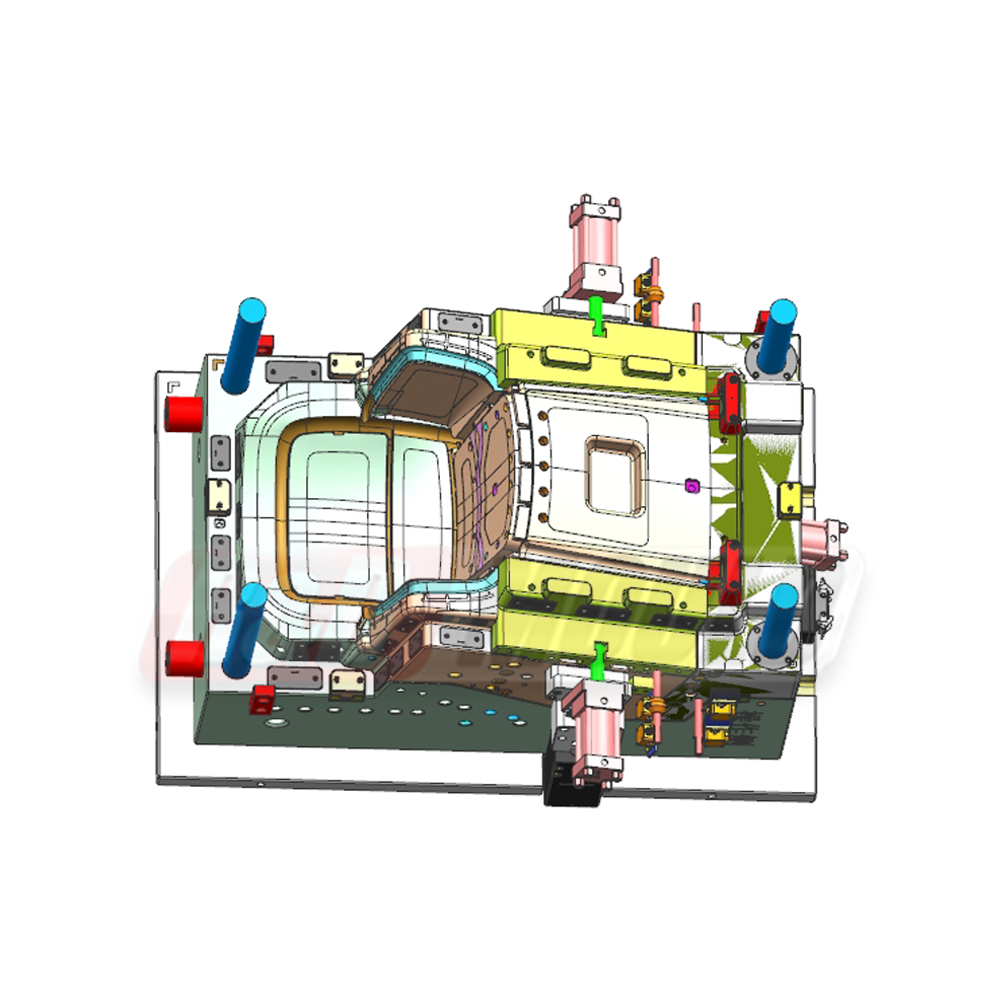

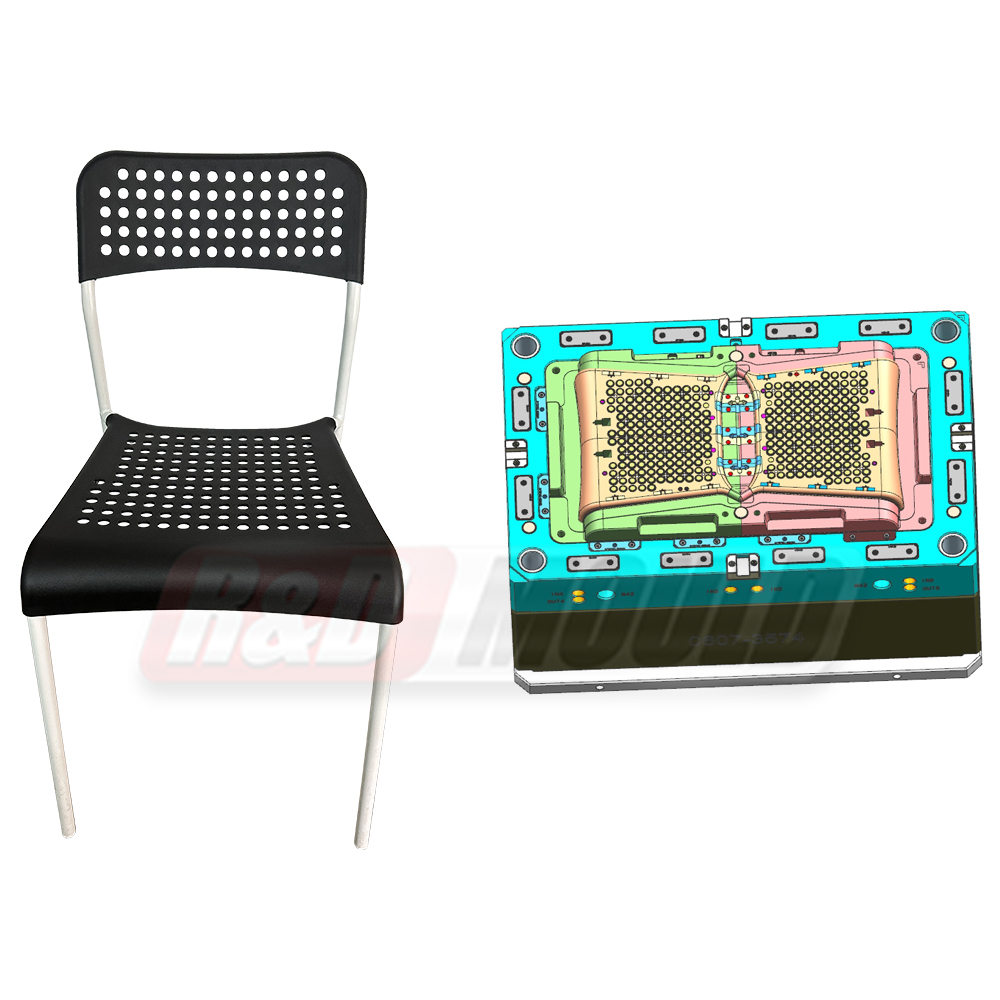

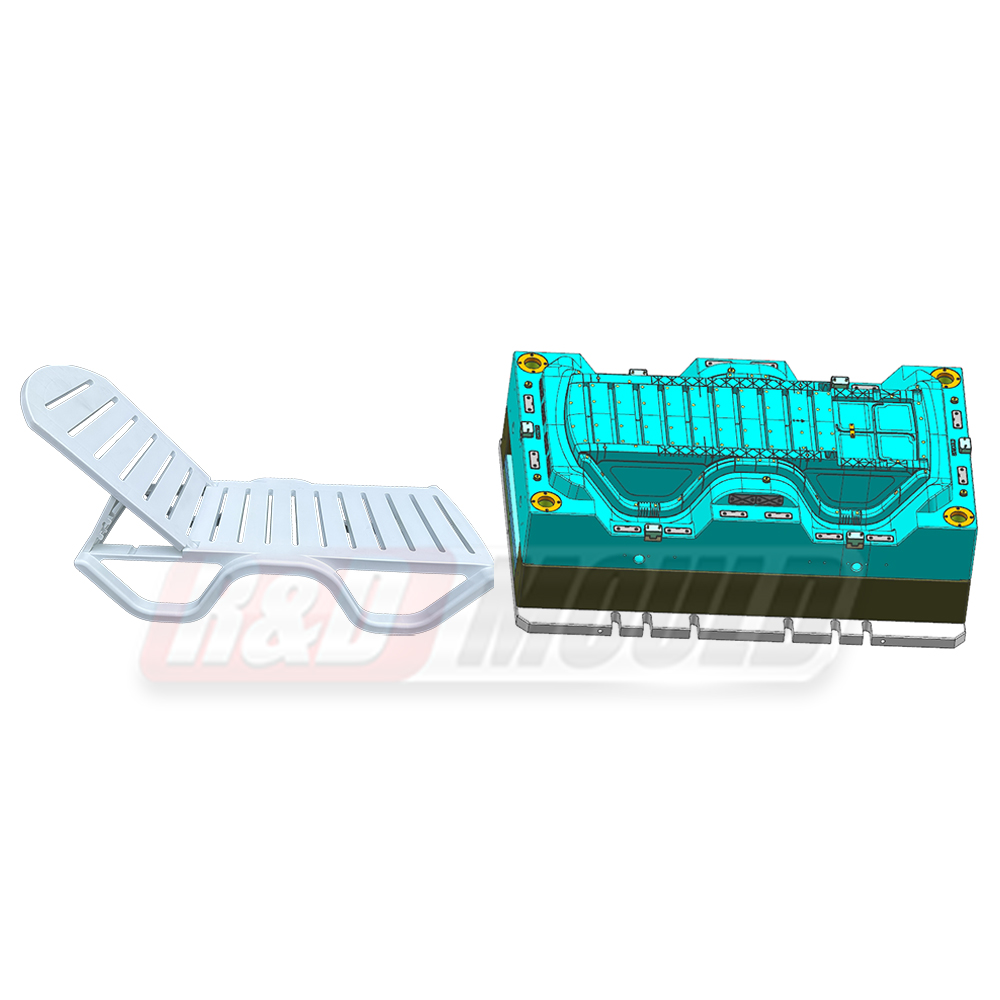

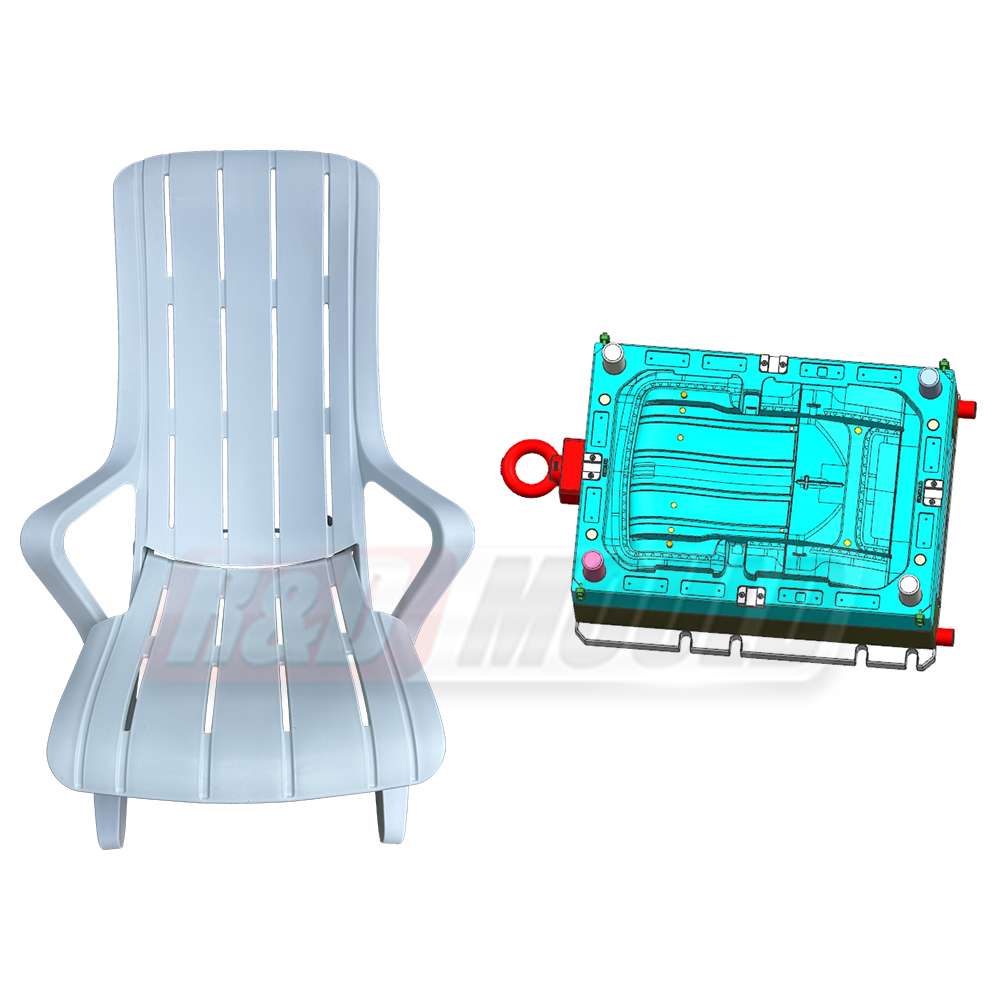

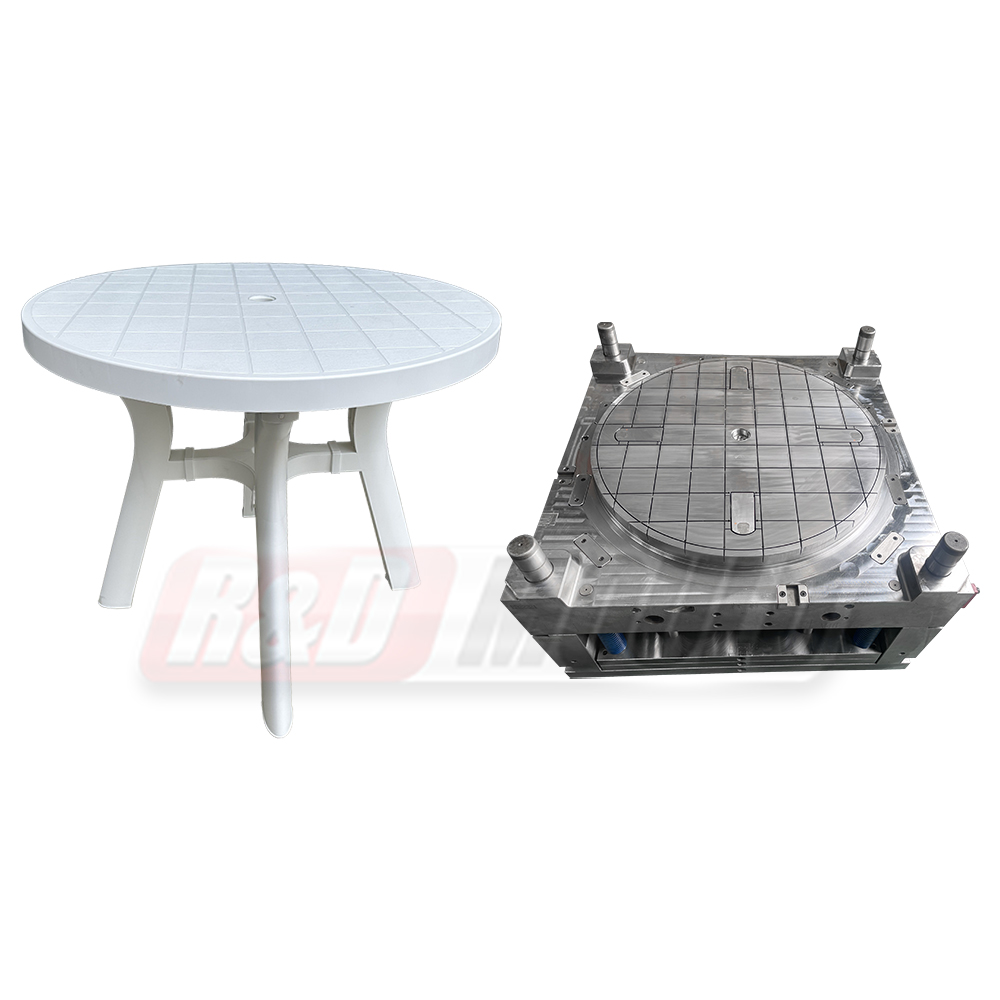

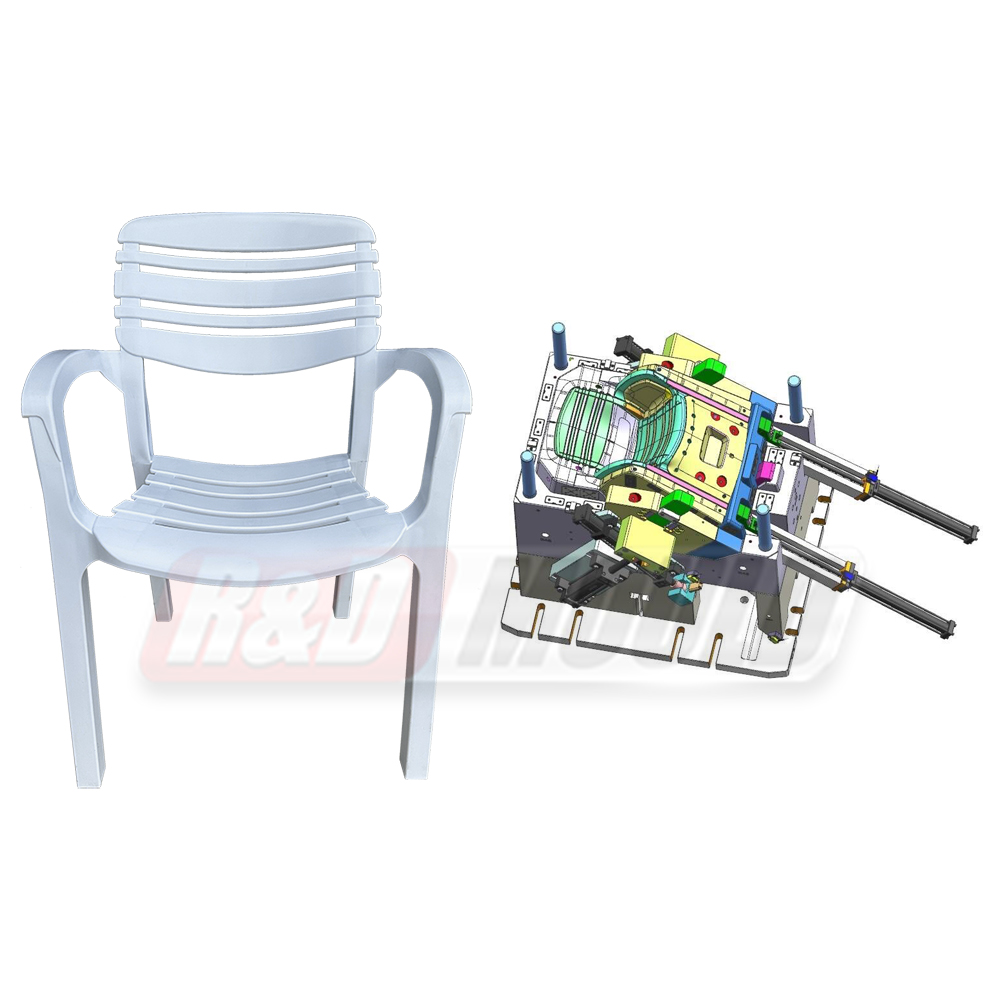

Gas-Assisted Injection Chair Mould |

|

Plastic Material |

PP |

|

Mold cavity/core steel |

P20 |

|

Runner /Gate system |

Hot runner |

|

Manufacture time (day) |

70days |

|

Mold life |

500,000shots |

|

Machine size |

780Ton |

|

Demolding |

Robot /Automatic |

with standard hardness for cavity and core, Germany steel for cavity and core, high speed injection, fully automatic ejection system.With years of working experience and state-of-the-art equipment, we can guarantee our customers high quality products, timely delivery and competitive price.

After-Sales Services

Experienced engineers will provide all-round technical solutions to any problems occurred in customers' mould operation.

Advantage

High efficiency, short delivery time, competitive price.You may send your requirement, or 2D, 3D design to us, We can make chair mould exactly as your needs.

R&D Mould offers full service ranging from the original conception to product completion, totally the whole solution from the paper sketch to the functional part in your hand.

1. Mold can produce all kinds of plastic products.

2. Can rapid prototyping.

3. Safe and fast delivery.

4. Quantity, good quality and reasonable price.

5. Support OEM.

6. The high quality service.

7. Customer requirements identified and welcome customer's design.

8. We have rich experience in mold production design and strict management system.

9. Provide the best after-sales service

English

English عربى

عربى Español

Español Français

Français