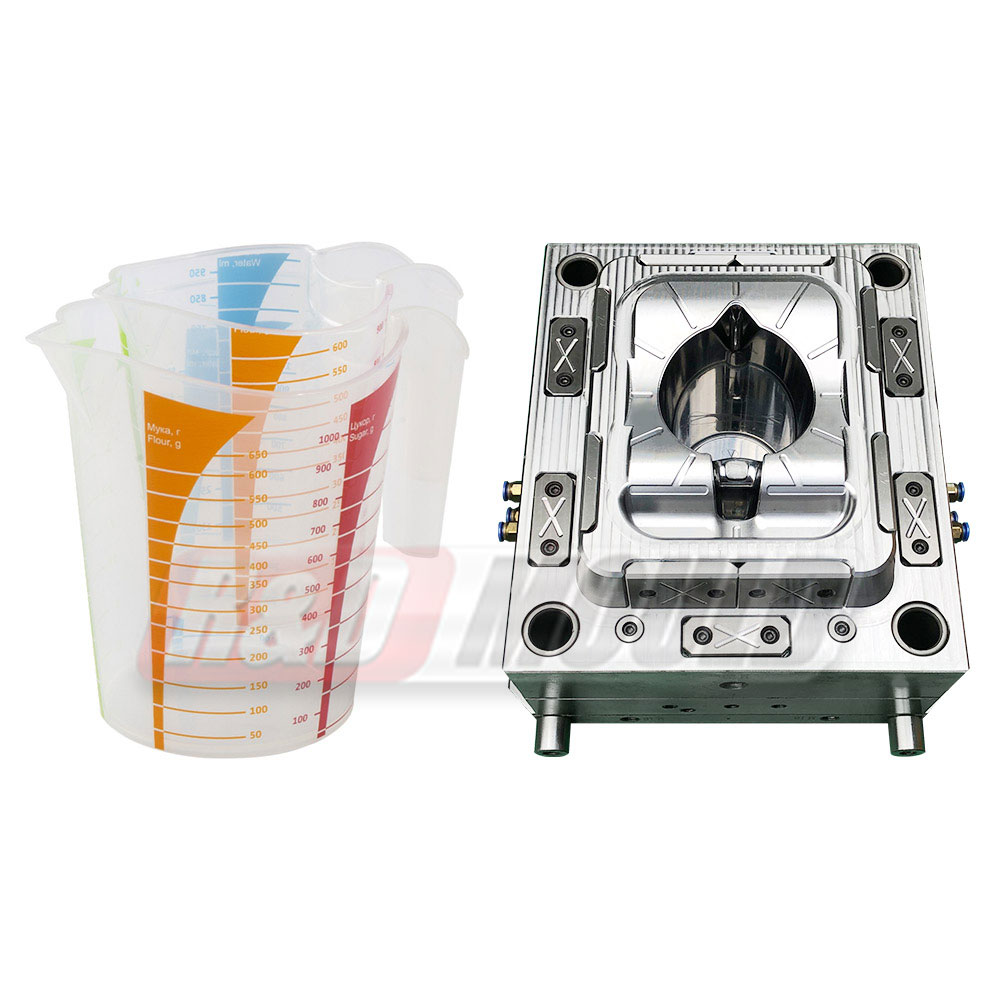

| Mold Name | IML Cup Mould |

| Plastic Material | PP Transparent |

| Mold Cavity/Core Steel | H13 |

| Runner /Gate System | Hot Runner |

| Manufacture Time (Day) | 40 Days |

| Mold Life | 1Milion Shots |

| Machine Size | 160Ton |

| Demolding | Full Automatic |

With more than 15 years' IML mould making experience, R&D Mould will offer you the best design for reasonable arrangement of gate and the best cooling for IMl mould. We guarantee you competitive price, high quality and prompt delivery. We have won a good reputation from customers around the world.

English

English عربى

عربى Español

Español Français

Français-1.jpg)

.jpg)

.jpg)