|

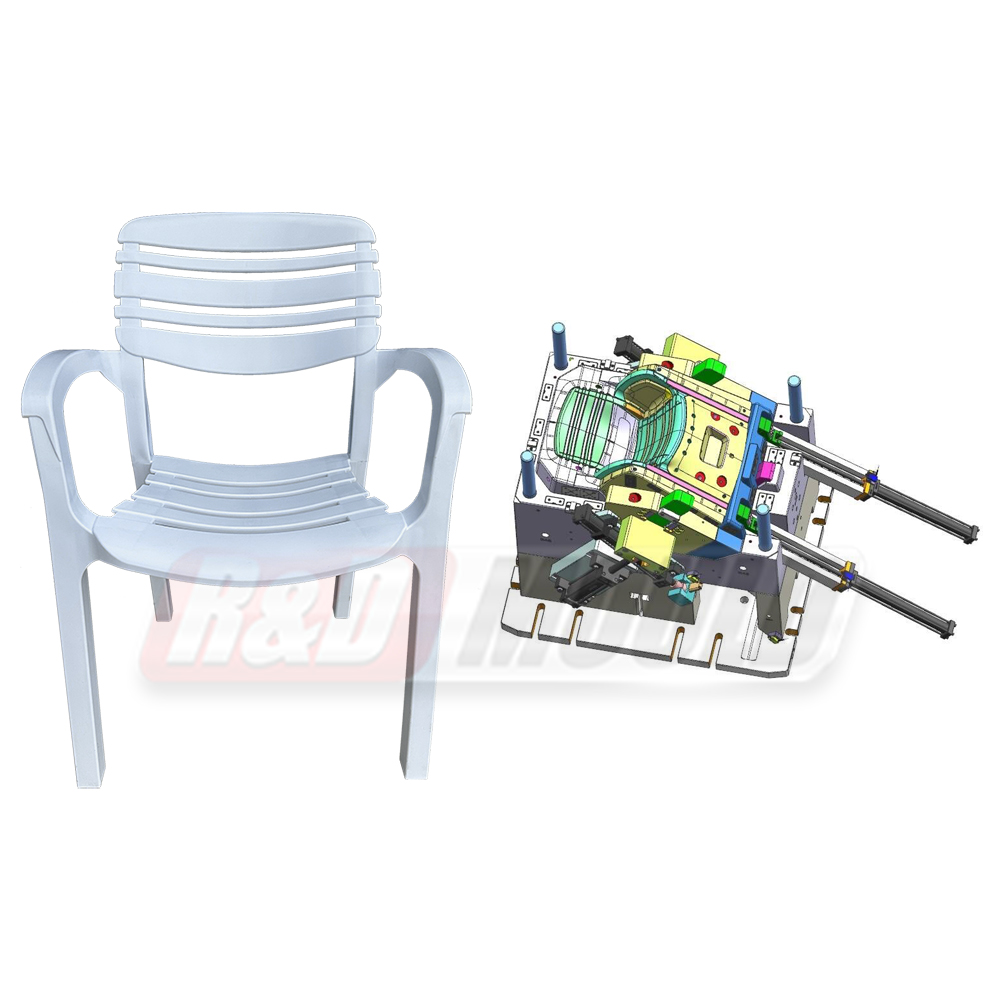

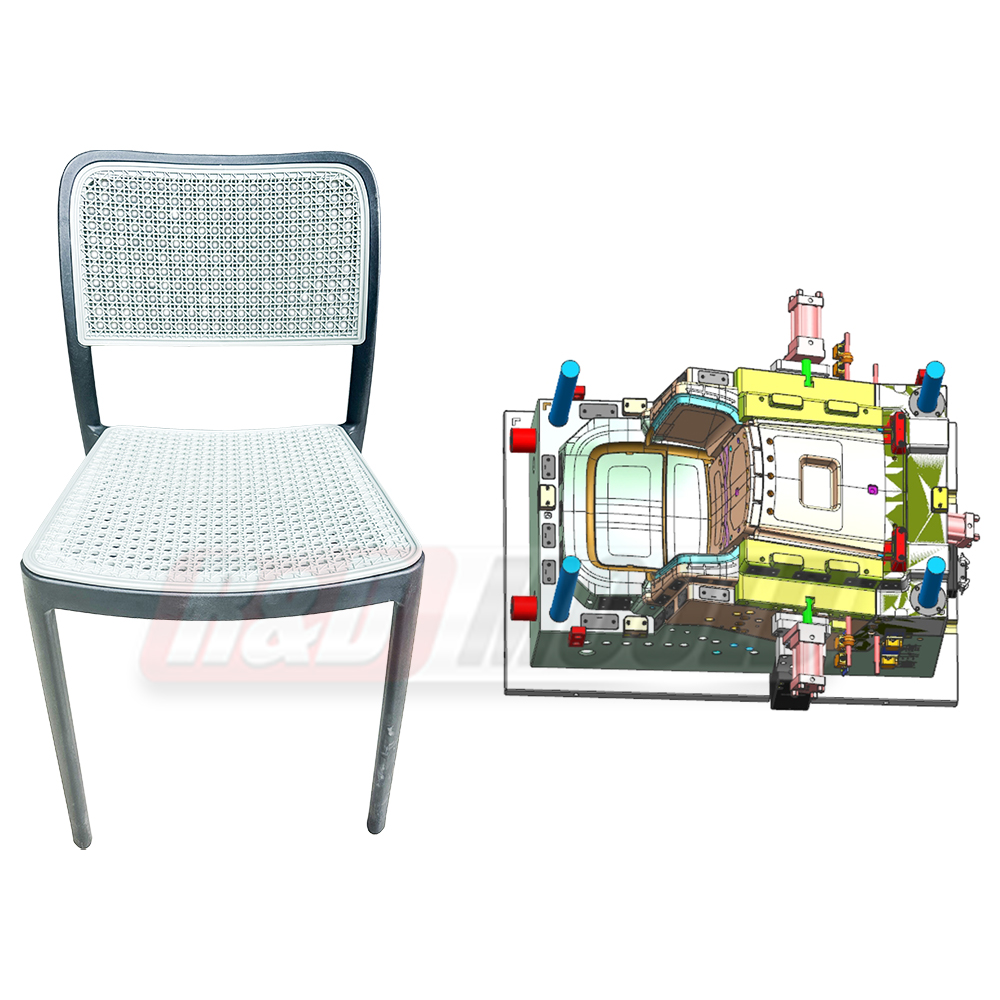

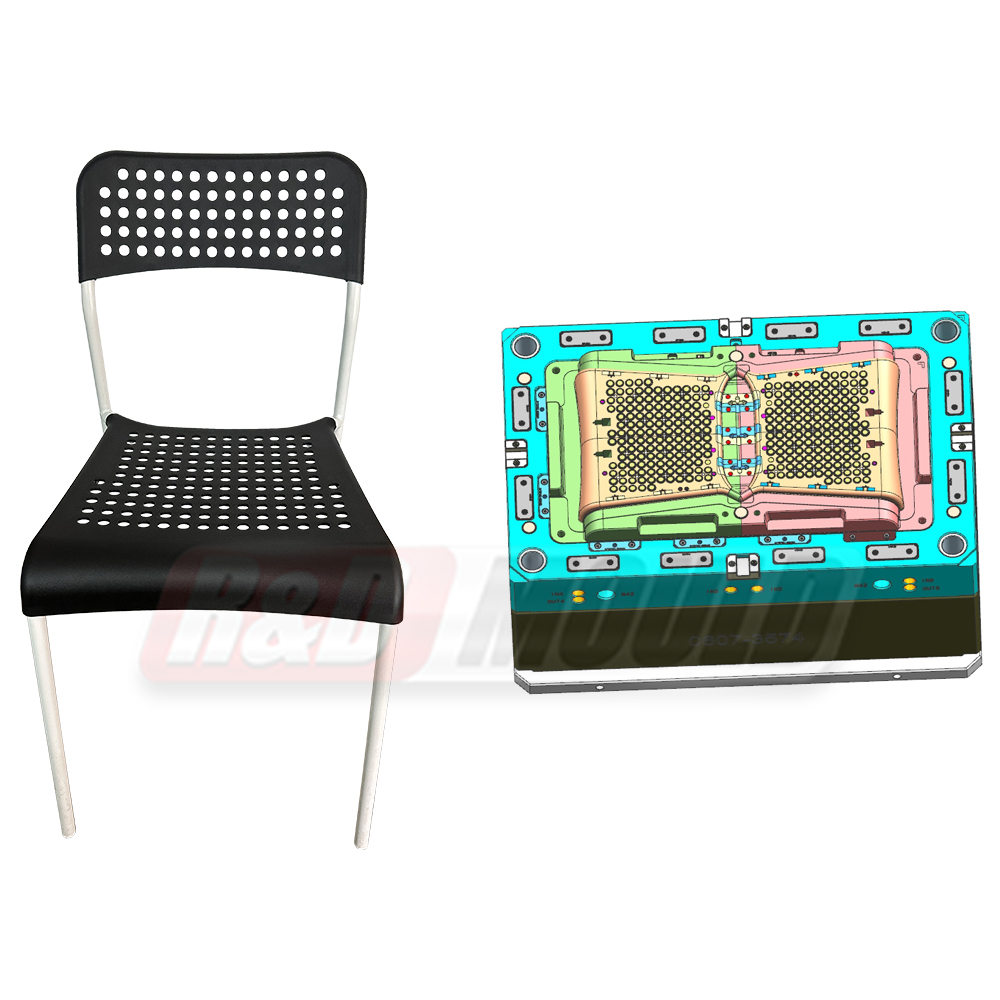

Product Name |

Rattan Chair Mould |

|

Product Material |

PP |

|

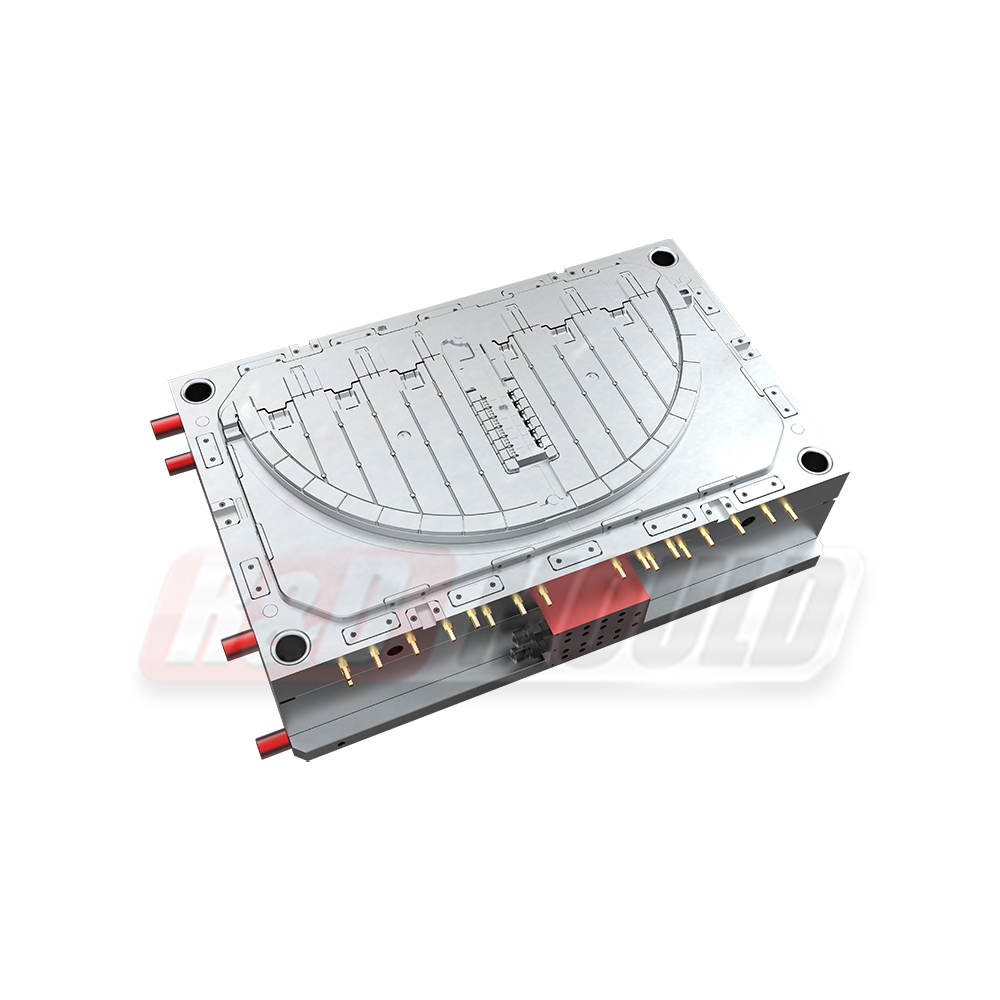

Mould Material |

718 |

|

Mould Cavity |

1 |

|

Runner Type |

Hot runner |

|

Mould Life Guarantee |

500,000shots |

|

Manufacture time (day) |

60 days |

|

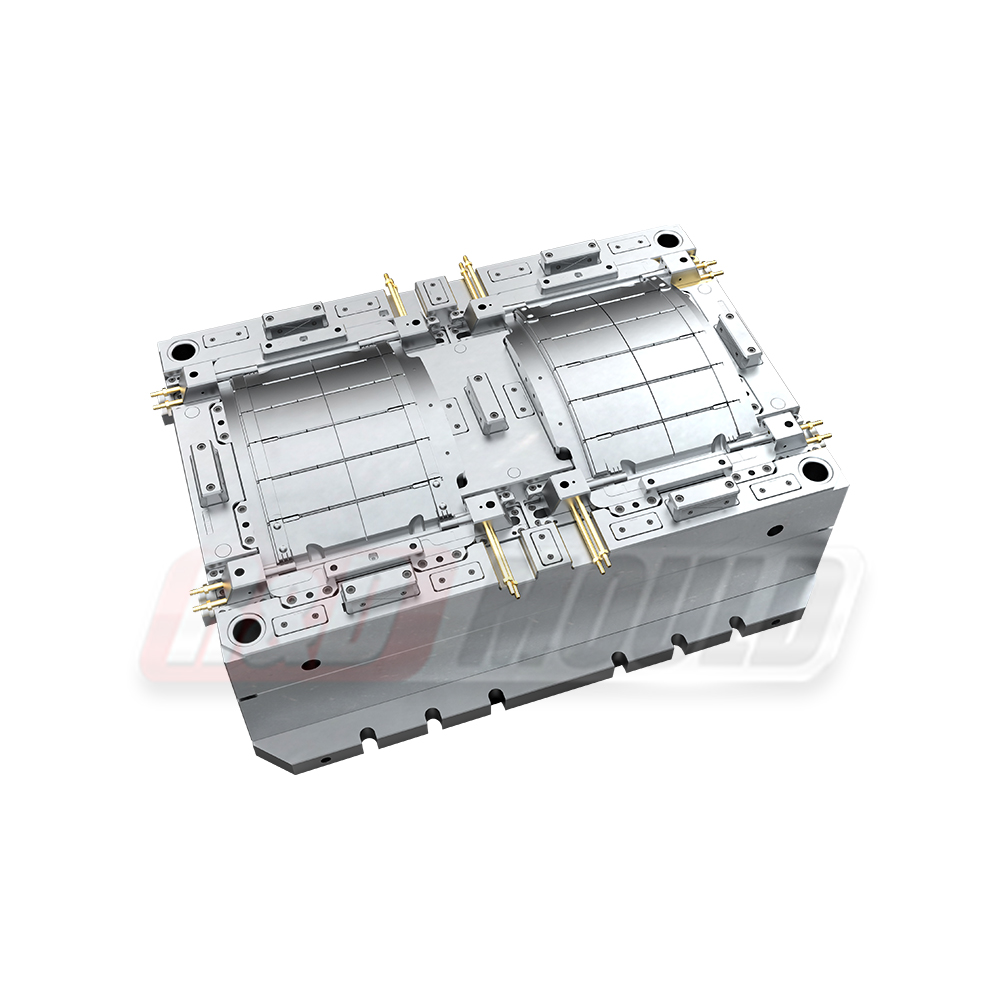

Demoulding |

Full automatic |

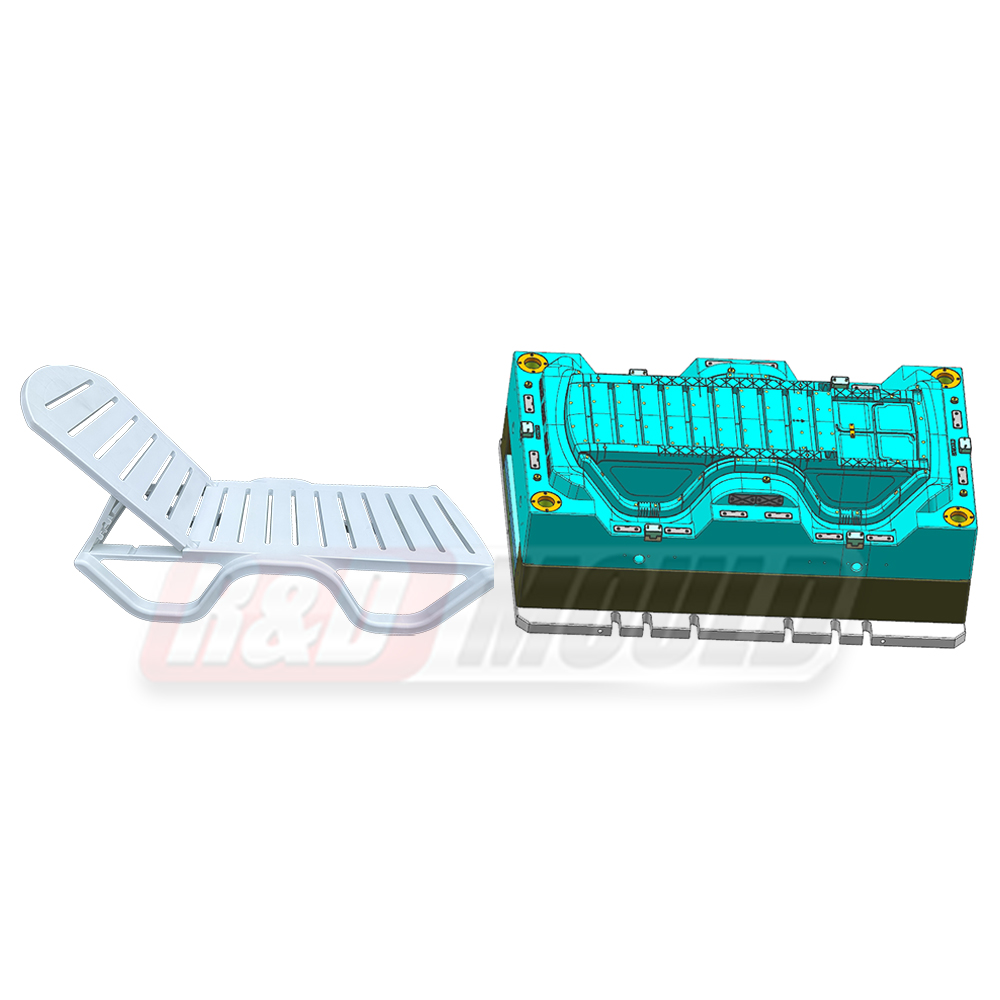

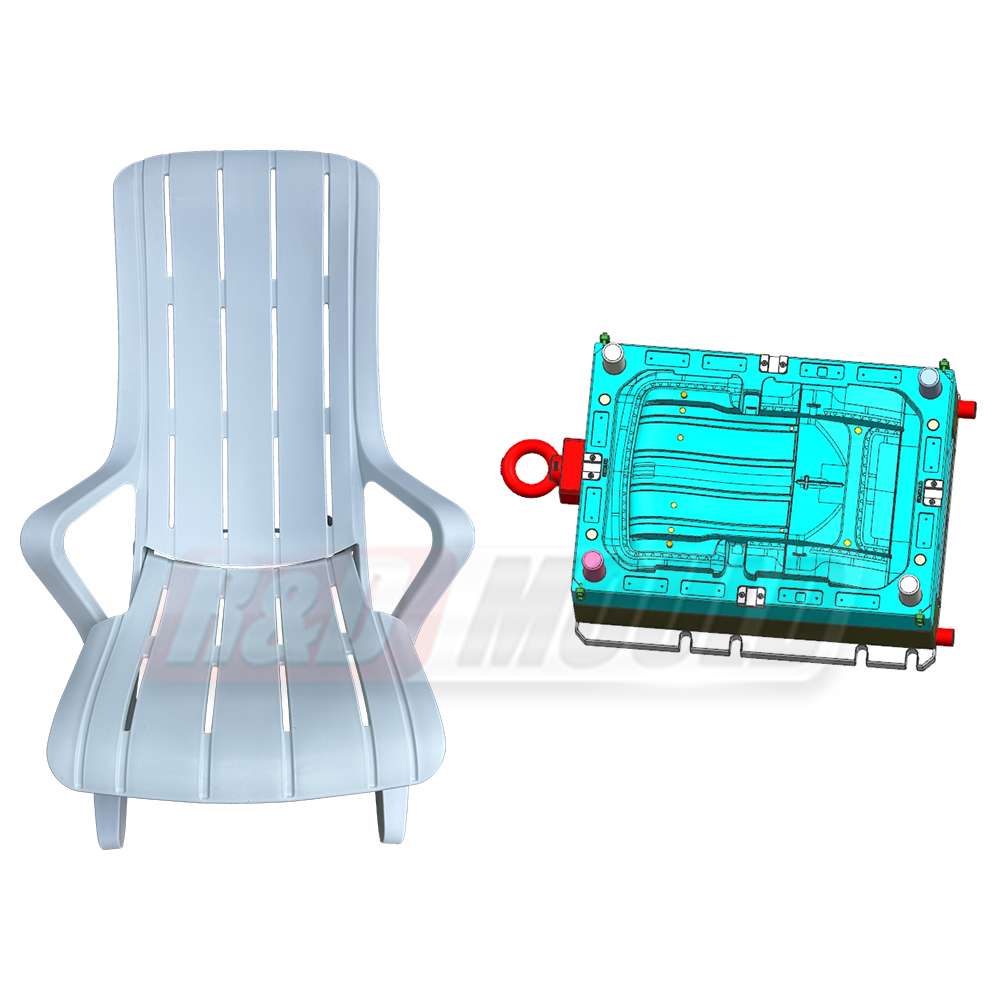

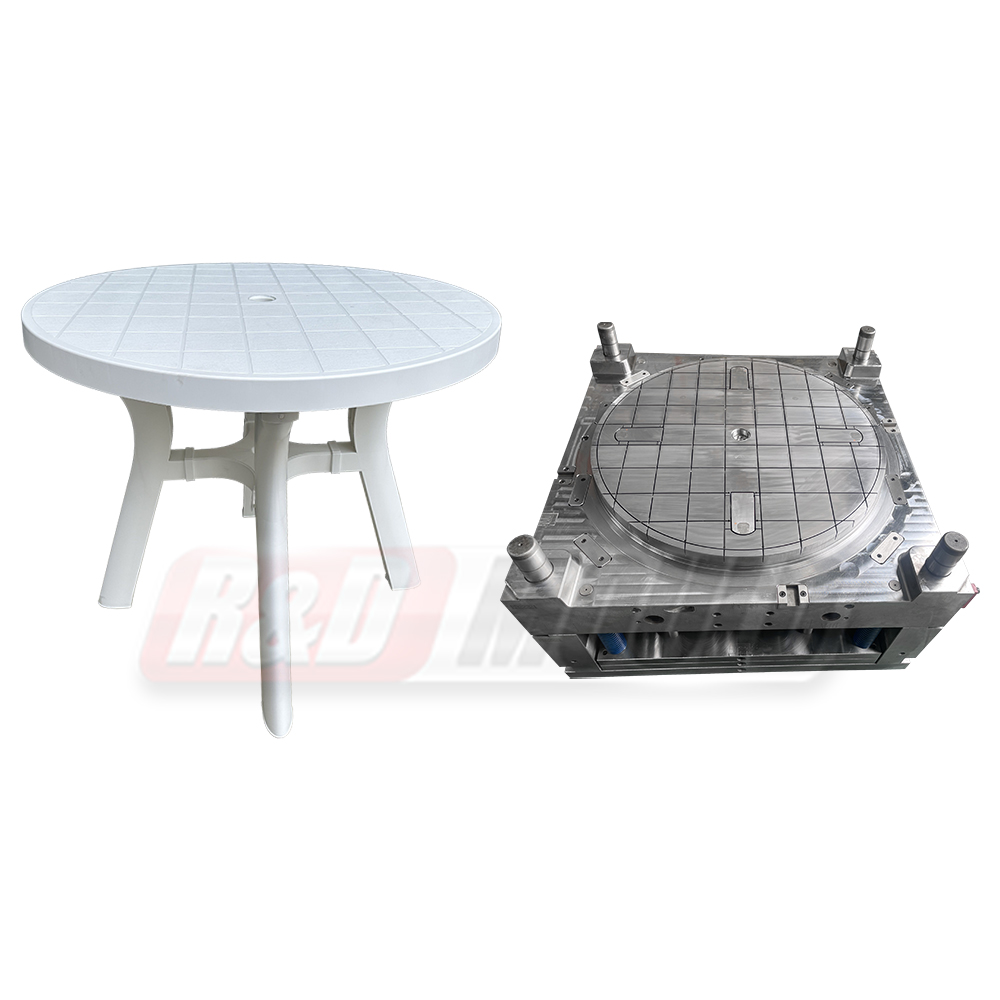

R&D Mould have 18 year experience on manufacturing Foldable Chair Mould, Rattan Chair Mould, Dining Chair Mold, Table mould and stool mould with various shape and sizes.

Core cavity material usually use:P20 (1.2311) , H13, 718H,2738...

Mould base: Long Kee standard mold base,

Mould Components: DME/ HASCO standard parts.

Surface treatment: According to product requirements, including skin texture, polishing;

Runner options: 1. Cold runner 2. Hot runner 3. Cold runner + hot runner

We offer the following solutions to our clients in product development. As follows:

1. Production equipment: CNC Machine :5pcs,High Speed CNC Machine:3pcs,EDM Machine:5pcs,Deep Hole Drilling Machine: 2pcs,Wire Cutting Machine: 5pcs, Carving Machine:5pcs, Mould Fitting Machine: 1pcs, Inspection Machine: 1pcs, 170T-470T HAITIAN Injection Molding Mchine :3pcs

2. Cooling system:Optimized design of circulation cooling line, improve production efficiency

3.Treatment: tempering to improving hardness. Post-treatment: Nitriding (Nitriding treatment temperature is low, the deformation is small, no need for quenching, with high surface hardness (greater than HV850) and wear resistance)

4.Mould life: P20 steel No less than 500,000 mold times in normal use

5.Mold warranty 1 year, free maintenance during the warranty period.

Note: In the process of mold production, we will provide mould process report to customer every week

English

English عربى

عربى Español

Español Français

Français