|

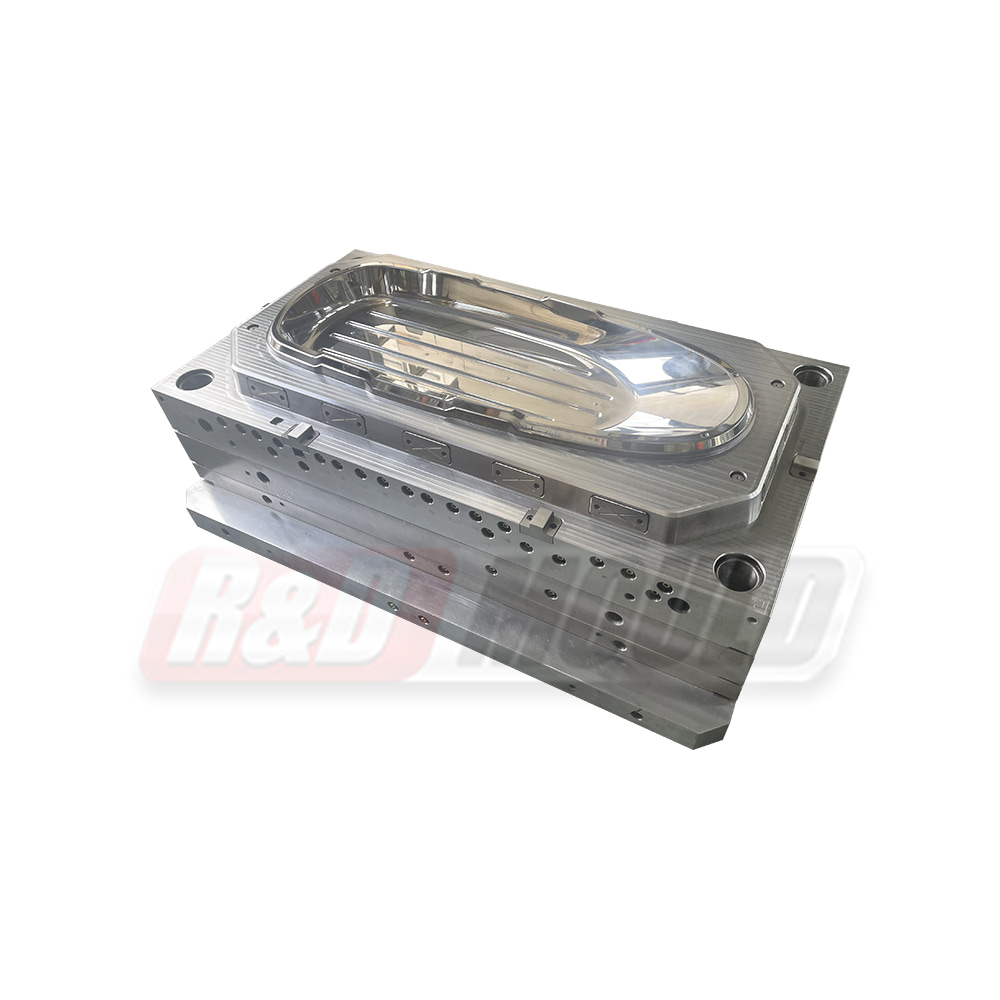

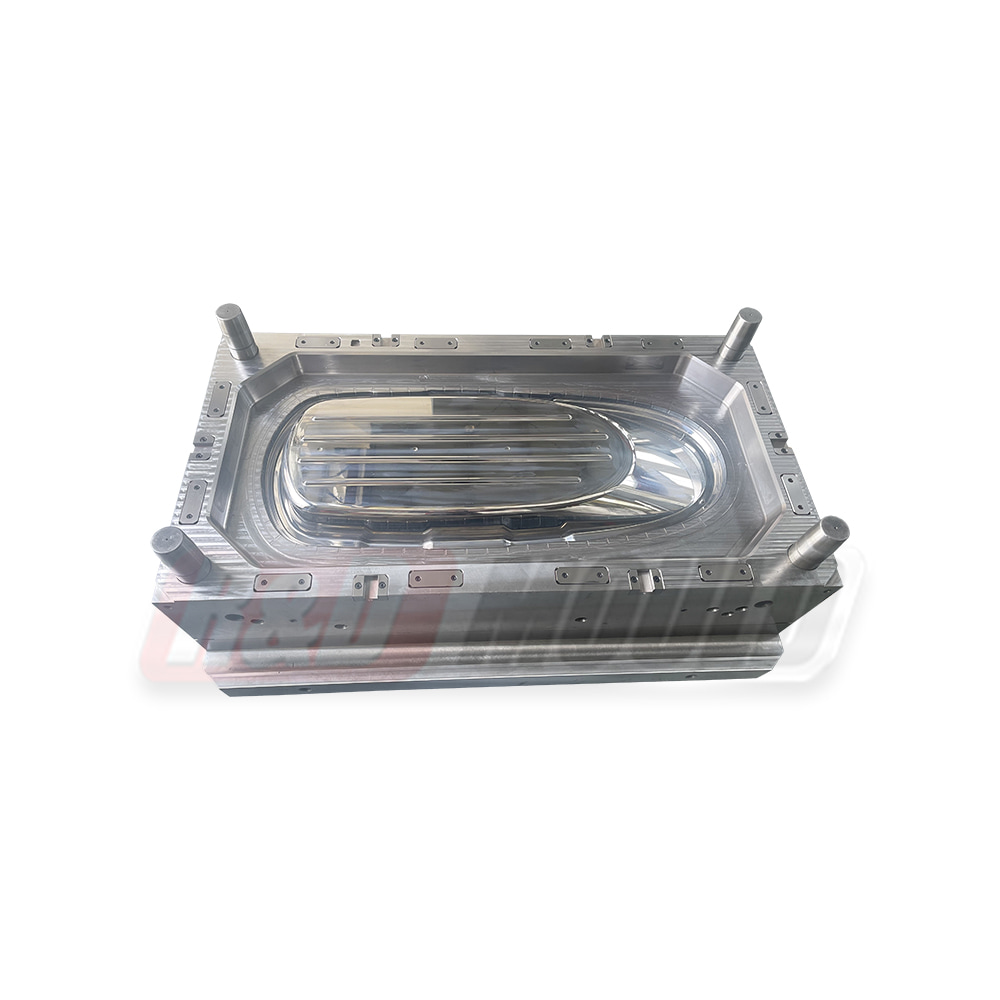

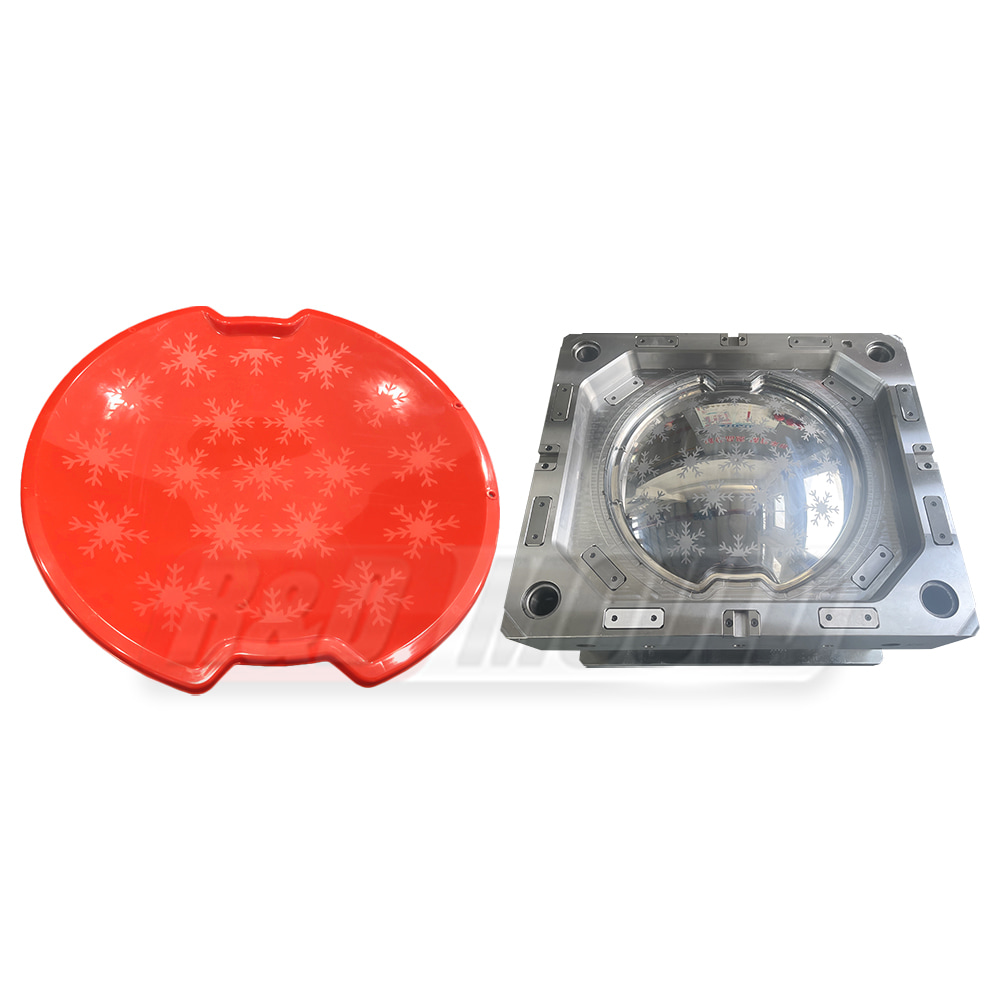

Product Name |

Small Sled Mold |

|

Product Material |

HDPE |

|

Mould Material |

USA P20 |

|

Mould Cavity |

1 |

|

Runner Type |

DME4 point gate |

|

Mould Life Guarantee |

300,000shots |

|

Manufacture time (day) |

50 days |

|

Demoulding |

Full automatic |

R&D Mould have 18 year experience on manufacturing Plastic Sled Mould with various shape and sizes.

Core cavity material usually use:P20 (1.2311) , H13, 718H,2738...

Mould base: Long Kee standard mold base,

Mould Components: DME HASCO standard parts.

Surface treatment: According to product requirements, including skin texture, polishing;

Runner options: 1. Cold runner 2. Hot runner 3. Cold runner + hot runner

We offer the following solutions to our clients in product development. As follows:

1. Production equipment: CNC Machine :5pcs, High Speed CNC Machine:3pcs , EDM Machine:5pcs , Deep Hole Drilling Machine: 2pcs, Wire Cutting Machine: 5pcs, Carving Machine:5pcs, Mould Fitting Machine: Ipcs, Inspection Machine: 1pcs, 170T-470T HAITIAN Injection Molding Mchine :3pcs

2. Cooling system:Optimized design of circulation cooling line, improve production efficiency

3.Treatment: tempering to improving hardness. Post-treatment: Nitriding (Nitriding treatment temperature is low, the deformation is small, no need for quenching, with high surface hardness (greater than HV850) and wear resistance)

4.Mould life: P20 steel No less than 500,000 mold times in normal use

5.Mold warranty 1 year, free maintenance during the warranty period.

Note: In the process of mold production, we will provide mould process report to customer every week

English

English عربى

عربى Español

Español Français

Français